Walk the docks at your local poker run and you’ll see everyone gawking at fancy paint jobs or oohing and aahing at the big blowers and the glimmering exhaust pipes. Few people walk around, look at the back of the boat and say, “Sweet Number Sixes.”

Despite the fact that Mercury Racing’s Dry Sump Six or the old wet-sump version is the most popular stern drive to pair with engines that put out more than 800 hp, it’s the most overlooked propulsion system component in the go-fast world. It’s quite possibly the ultimate compliment to the technical and engineering marvel that is the Number Six drive. It’s just so reliable and so bulletproof.

Still, like any other piece of mechanical equipment, a Number Six needs to be serviced routinely for it to have a long, hassle-free life. This is not a job for just any shop or mechanic flying a MerCruiser flag. But while there are several experts including Jason Ventura at Brand X (who also has had several years of experience working with Outerlimits), Larry Goldman at Extreme Marine, Randy Garcia of Cobra Marine, and Rick La More at Innovation Marine, just name a few of the performance boating gurus in the industry, these five guys over the following pages do nothing but outdrives, and have honed their expertise to the highest level.

To order a back issue call (800) 461-9128 or sign in to read entire article

John Klumpjan

Doller Offshore Marine

Fort Lauderdale, FL.

The elder statesmen and acknowledged guru of the performance sterndrive, John Klumpjan started in 1968 with Carl Kiekhaefer and his company Kiekhaefer Aeromarine before it became Mercury Hi-Performance and eventually Mercury Racing.

The elder statesmen and acknowledged guru of the performance sterndrive, John Klumpjan started in 1968 with Carl Kiekhaefer and his company Kiekhaefer Aeromarine before it became Mercury Hi-Performance and eventually Mercury Racing.

Klumpjan had worked with a farm machine manufacturer and was experienced with gears and hydraulics. When that company fell on hard times, Klumpjan, who was from Fond du Lac, WI., the home of Kiekhaefer Aeromarine, called on Kiekhaefer’s company. Klumpjan’s high-school friend Mel Riggs was working for Kiekhaefer and between Riggs’ endorsement and a glowing reference from the farm machine company, Klumpjan got the job. He was assigned to assist engineer Larry Lohse, who would be instrumental in developing the first Speedmaster drive (the Speedmaster III). Klumpjan put his experience with bearings and gears to work, building the first Speedmasters often with Kiekhaefer looming over his shoulder. As the company introduced the Speedmaster IV and V, more race teams were using them and they only wanted one guy to rebuild them when that time came — that guy was Klumpjan.

“I have 16 world championships and eight of those were with Aeromarine,” said Klumpjan who is now 70 years old. Among the teams/owners that demanded that Klumpjan rebuild their drives were Jerry Jacoby of Ajac Hawk fame, Dr. Bob Magoon, Tom Gentry, Don Johnson, Bob Saccenti, Craig Barrie, Bernie Little and Renato Della Valle, whom Klumpjan referred to as “The Italian Donald Trump.”

He found his way to Florida in the late 1970s working for Jacoby’s company, Hawk Marine Power. When Jacoby decided to partner up with the late Don Aronow and Cigarette Racing Team, Klumpjan moved with him and figured his future was all set building drives for Aronow. We all know what happened there.

Klumpjan joined Doller in 1988, working with fellow Team 6 members Matt Gilvey and Brian Jackson (more on them later), making Doller Marine the go-to shop for Speedmaster rebuilds. In 1995, Ron merged the company with Offshore Marine to form Doller Offshore Marine in Fort Lauderdale. Upon Ron’s unexpected death, his wife Mindi, along with the long-time employees, have expanded and moved the company to its current location in Hollywood, FL.

Klumpjan wants to retire, but is now on a part-time basis, coming in when Mindi Doller has a Number Six or another big drive needs to be worked on.

“The key to doing an outdrive right, whether if it’s a 6 or an 8, is setting the gears to the horsepower and torque,” said Klumpjan. “It’s more important than ever because of the horsepower being created.”

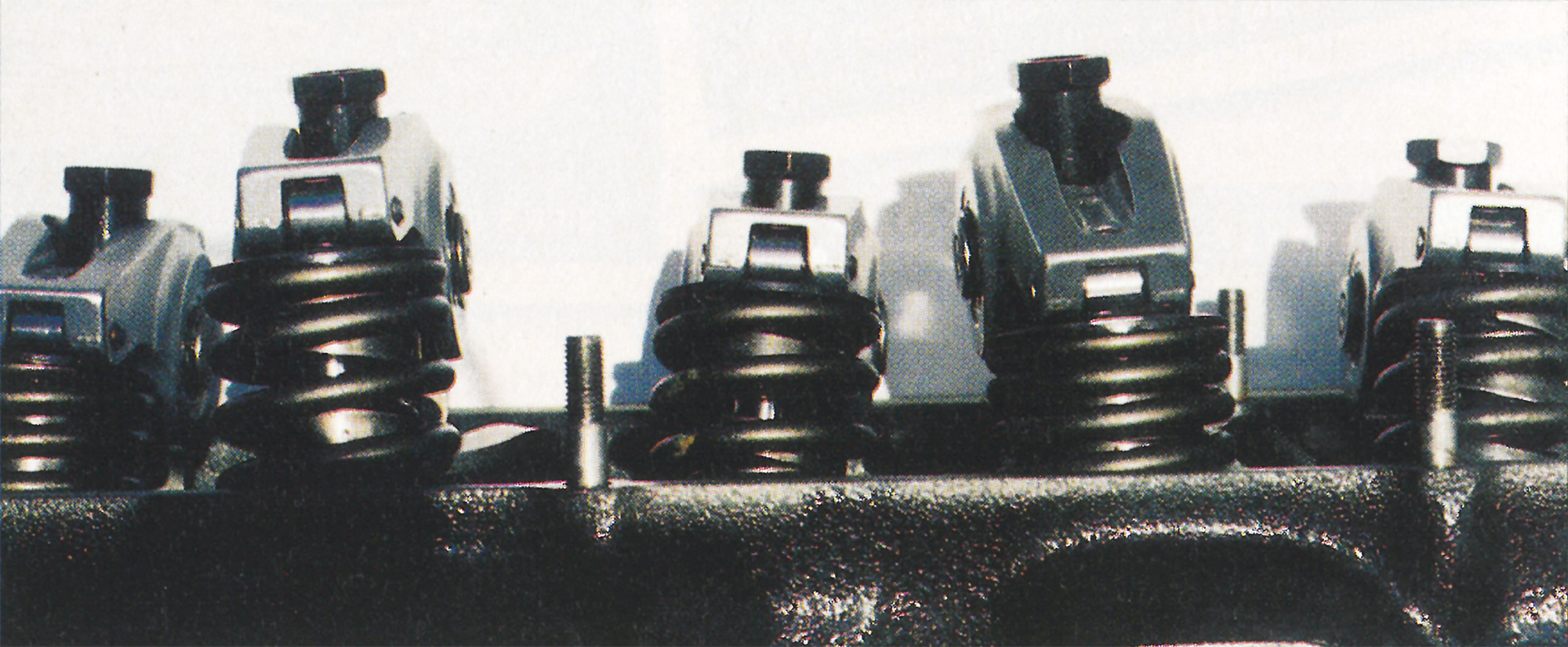

Klumpjan said that he believes that the Dry Sump Six is actually easier to work on than the Speemaster III, IV or V because of the immense size of all the components. The most critical part of the rebuild in his eyes is properly loading the spur and helical gears before making the final settings. He does disagree with some of his colleagues that the upper gearsets are often the first to go in a Number Six. “The only reason it would go is if something plugged the oil from getting to the upper,” he said.

He said that the most important thing owners can do to extend a Number Six drive’s life is to keep up with oil changes. After the first 25 hours, or break-in, oil should be changed every 50 hours. Drives should be gone through to replace seals, check gears and reset lash and other sittings every 100 hours. To rebuild a Dry Sump six, Doller Offshore Marine charges $1,200 plus parts.

For more information contact:

Doller Offshore Marine

Hollywood, FL

(954) 237-0332

www.dolleroffshore.com

Matt Gilvey

TNT Custom Marine

North Miami, FL.

An admitted fan of gears and bearings, 56-year-old Matt Gilvey originally wanted to work in the offshore sailing business when he entered the marine industry. In 1975, he was a certified Volvo Penta sterndrive mechanic when he went to work for Merrill Stevens Shipyard in 1976. Gilvey then moved onto Custom Engine Service in Hialeah, FL., in 1981 where he focused on rebuilding and repairing drives. “Everybody wanted to build engines or do electrical or rigging,” said Gilvey. “Nobody wanted to do sterndrives because they were afraid of them. People don’t understand setting up backlash or bearing preload.”

An admitted fan of gears and bearings, 56-year-old Matt Gilvey originally wanted to work in the offshore sailing business when he entered the marine industry. In 1975, he was a certified Volvo Penta sterndrive mechanic when he went to work for Merrill Stevens Shipyard in 1976. Gilvey then moved onto Custom Engine Service in Hialeah, FL., in 1981 where he focused on rebuilding and repairing drives. “Everybody wanted to build engines or do electrical or rigging,” said Gilvey. “Nobody wanted to do sterndrives because they were afraid of them. People don’t understand setting up backlash or bearing preload.”

After honing his skills on yachts from Hatteras, Bertram and others, Gilvey teamed with Klumpjan at Doller Marine in 1988. From the start, he worked on Speedmaster III and IV drives. “The Number Six came out around 1990 and the first set I worked on were with an old 41’ Apache sponsored by Doller Marine,” he said. This is where Gilvey met John Tomlinson for the first time while working on his boat, Doller Marine Special. It was also around this time when Gilvey received the Mercury Marine Master Technician Award in 1993.

When Doller merged with Offshore Marine to form Doller Offshore, Gilvey accepted an offer to go work at Bobby Moore’s Custom Marine. He worked at Bobby Moore’s for four years, before winding up at TNT in 1999, where he is today. Gilvey heads up the drive department, which also works on Arneson and BPM surface drives, including those being used on turbine-powered boats like Miss GEICO, JBS Racing and more. “I probably do more BPM work here than anyone else in the country,” said Gilvey.

He estimated that he used to rebuild about 20 Number Six drives per year when they first came out. “I’ve done more than 20 in one month in past years,” he laughed. He has an apprentice, Eddie Sidron, who is learning at the hands of the master. The mantra that Gilvey will surely pass on to Sidron is “We have to build a stern drive like our life depends on it because somebody else’s life does depend on it.”

TNT currently has two locations, the marina and a removed warehouse/rigging facility about 1/2 mile away where the drive rebuilds take place.

He said that complacency is the biggest mistake someone can make after having success rebuilding a couple of drives. “Each one is its own individual. We take a lot of care to begin with. We maybe take a few extra steps in doing these and are a little more critical in the clearances and how they do move.”

Gilvey said that upper gearsets take the most abuse, depending on how hard owners are on their equipment. Like his compatriots, he said that the biggest concern he has when he rebuilds a Number Six is setting the load on the two spur gears. These are the gears that sit atop the two vertical shafts in the gear case. If you don’t get the load evenly balanced between the two, the engine’s power won’t be distributed evenly. This can shorten drive life. “That’s kind of like an acquired talent,” he said. “If you’ve done enough of them you can usually get it right on.”

For more information contact:

TNT Custom Marine

North Miami, FL. (305) 947-6088

www.tntcustommarine.com

Brian Jackson

Offshore Outdrives

Fort Lauderdale, FL.

After I hung up from our phone conversation for this article, Brian Jackson, owner of Offshore Outdrives, called back within minutes. “I forgot one thing,” he said. “When I worked with Matt, the one thing he would say is, ‘Brian build these drives like your life depends on it.’” Jackson couldn’t have learned from two more talented technicians than Klumpjan and Gilvey. He started at Doller Marine in 1989 after working for Miami-Dade Truck as a painter. Doller Marine needed a drive painter and when Jackson stopped by looking for a job, he told them they were using the wrong catalyst in their drive paint.

After I hung up from our phone conversation for this article, Brian Jackson, owner of Offshore Outdrives, called back within minutes. “I forgot one thing,” he said. “When I worked with Matt, the one thing he would say is, ‘Brian build these drives like your life depends on it.’” Jackson couldn’t have learned from two more talented technicians than Klumpjan and Gilvey. He started at Doller Marine in 1989 after working for Miami-Dade Truck as a painter. Doller Marine needed a drive painter and when Jackson stopped by looking for a job, he told them they were using the wrong catalyst in their drive paint.

“Ron Doller said, ‘You’ve got the job,’” Jackson recalled. He started painting drives and slowly worked his way into taking apart the drives and cleaning them, learning as he went. Observing Gilvey and Klumpjan further piqued Jackson’s interest in working on drives. “I saw the engine part of it and the rigging part of it and I wanted to do drives,” he said.

He went to school for Speedmasters and when Gilvey left to go to Bobby Moore’s Custom Marine, Jackson worked with Klumpjan continuing to learn for another two years before he decided to go to TNT. Following the two years, he started his own business, Offshore Outdrives in Fort Lauderdale.

Today Offshore Outdrives lists among its clients the Cintron racing team, the Stihl-sponsored Super Cat Light Skater 38, Team Loriblu’s MTI, the Firewater Fountain and a host of poker run boats. At age 43, Jackson is also one of the most sought after builders of outboard gearcases for Super Stock teams like Mojo, The Hulk and Talbot.

“It’s all trust,” he said. “Everyone brings the stuff now because we’ve established that trust.” Jackson said that in addition to setting the load on the spur gears correctly, the pinion height and the shimming of the gears become critical when engines are putting out 1,500 hp. He said that the biggest factors in determining how often drives need to built are the power running through them and how hard the operator is on the equipment.

While Jackson currently works on the Cintron team’s 50’ Mystic with BPM drives, in recent years, he has worked on the teams’ Dry Sump Six drives for its previous 40’ Platinum catamaran, which were rebuilt every two races to keep up with their 1500 hp Stotler Racing Engines. Offshore Outdrives charges $1,350 plus parts to rebuild a Dry Sump Six.

For more information contact:

Offshore Outdrives

Fort Lauderdale, FL. (954) 448-4478

Info@offshoreoutdrives.com

Offshoreoutdrives.com

Craig Colabella

Colabella Performance

St. Cloud, FL.

In 1979, Craig Colabella was running endurance boats for Mercury Marine at Lake X and after the company closed the endurance department, it was just one-year later when Don Schwebbs, who was the manager at Lake X, hired Colabella in 1980. Schwebbs immediately sent him to Wisconsin to Speedmaster drive school when Mercury Marine bought Kiekhaefer Aeromarine.

In 1979, Craig Colabella was running endurance boats for Mercury Marine at Lake X and after the company closed the endurance department, it was just one-year later when Don Schwebbs, who was the manager at Lake X, hired Colabella in 1980. Schwebbs immediately sent him to Wisconsin to Speedmaster drive school when Mercury Marine bought Kiekhaefer Aeromarine.

“I basically was the first one,” he said. “I was there learning from Kiekhaefer as a Mercury employee.” Having a technician on-site that could rebuild Speedmasters made Lake X a more attractive test location. Colabella also taught the teachers who taught on the Speedmaster drives at Seminole Community College.

He stayed at Lake X until the facility shut down in 2009, working on drives for all of Mercury Racing’s customers. Soon after, Colabella Performance was founded and he instantly picked up many customers he had when he was still working for Mercury Hi-Performance/Racing. Today, Colabella Performance lists among its clients WHM Racing, and Team CRC. Joe Imprescia at East Coast Performance in West Islip, NY., on Long Island sends Colabella all his Number Six rebuilds. A number of shops on the West Coast also ship their drives to Colabella. He charges a $1,000 flat labor rate, plus parts to rebuild a Number Six. The typical parts list for a rebuild on an undamaged drive include the upper seal, split-line O-rings propshaft seals and the prop shaft seals and bearings.

Like our other experts, Colabella said getting the load right on the spur gears is the most critical step in a rebuild. In addition to the proper load, the gears need to be torqued in the correct rotation direction. But when it comes to learning to rebuild a Number Six, Colabella’s advice is, “There is only one way, learn to be a perfectionist.”

For more information contact:

Colabella Performance

St. Cloud, FL.

(407) 498-0094

www.colabellaperformance.com

Jeff Hopper Legendary

Performance Marine

Destin, FL.

Our other Lake X graduate, Jeff Hopper, started at the top-secret test facility in 1985 and stayed there for 25 years. In fact, Hopper spent approximately 20 of those years at the Lake X facility and the remaining five at the company’s “X” Site. “I started on the bottom level working for Don Schwebbs. He gave me a golden opportunity. Aside from having my own family, it was the best thing that ever happened in my life.”

Our other Lake X graduate, Jeff Hopper, started at the top-secret test facility in 1985 and stayed there for 25 years. In fact, Hopper spent approximately 20 of those years at the Lake X facility and the remaining five at the company’s “X” Site. “I started on the bottom level working for Don Schwebbs. He gave me a golden opportunity. Aside from having my own family, it was the best thing that ever happened in my life.”

Hopper said that Colabella took him under his wing and taught Hopper the nuances of the Number Six and all the Speedmasters. “Nobody else wanted to do it because everybody and their little brother cares about the engine and the noise,” said Hopper. “You don’t have a drive, you’re going nowhere.”

Colabella and Hopper were Mercury Racing’s dynamic duo at offshore races, saving teams’ weekends when they could rebuild drives in the company’s support truck on a Saturday night to get a boat back on the water on Sunday. “I miss going to the races, the faces and the people,” he said.

When Lake X closed in 2004, Hopper said he was offered an opportunity to move to the headquarters in Wisconsin, but he didn’t want to leave Florida. He then made the move to Nor-Tech Hi-Performance Boats building Speedmasters and Bravo’s for a year before working at Legendary Performance Marine in Destin, FL, where Hopper is currently setting up a drive repair shop.

When it comes to working on a drive like the Number Six or the new M8, one of which Hopper was rebuilding when we talked, he said, “You just need to give a damn. You can’t just throw the thing together. It’s more of an art than a science.”

He recalled one time when was rebuilding a Dry Sump Six and he had the spur gears all positioned to be loc-tited. Someone who didn’t know better walked up and picked up one of the gears. Hopper had to start all over. “Every time you touch one, you need to take off both and re-set them,” he said.

And you can never tell how long it will take to get the setting right. “I’m embarrassed to say how long it took me to get the spur gears right on an 8 drive yesterday,” he laughed.

Hopper was one of the first to rebuild the new drive and he said it’s more than just a bigger version of the Dry Sump Six. “It’s totally different gears, shafts, the whole thing is different,” he said. But one thing remains the same. If any of the members of Team Six is asked to rebuild one, the job will be done right.

For more information contact:

Legendary Marine

(Legendary Performance Division)

Destin, FL

(800) 337-2436

www.legendarymarine.com PRA