Let’s play some word-association. When I say, “Supercharger for performance boats,” what’s the first name that pops into your head? For most people in the go-fast-boat crowd, the name is Whipple.

The reason is simple. No supercharger manufacturer has worked harder in the last decade to provide a complete package to upgrade a typical performance boat engine.

“We’ll only build something if it can be 100 percent,” said Dustin Whipple, Vice President of Whipple Industries in Fresno, CA. “When we design a package we want to make sure we’re giving you all components as if you bought it from the factory, yet, giving you components that create envy every time someone lifts the hatch.”

The key to Whipple’s marine industry success comes down to having the ability to re-map or re-write the computer programming. Initially Dustin Whipple went to college for marketing, but soon realized a change was needed. “I realized that I’d be best suited for working on our products instead of just selling them,” he said.

So Dustin self-taught himself to calibrate the electronic control modules (ECMs) on popular high-performance marine engines to ensure that they would work properly with an aftermarket Whipple supercharger kit. Whether it’s a Mercury Racing HP 525 EFI, or the new 565 or 520 Sterndrive engines, Whipple Industries has developed a reliable supercharger kit for those engines.

“When we come out with the packages, we said, ‘We want it to live and we want the electronics to work,’” says Dustin.

Despite the fact that the marine business makes up approximately 15 percent of Whipple Industries’ overall sales, the family-business is committed to the high-performance boating world. Shonda Whipple, Art’s daughter, is married to Mike Fiore, owner of Outerlimits Powerboats in Bristol, RI, and she still takes care of the books for the company

Dustin had an Outerlimits 48’ catamaran and recently sold it, replacing the boat with an Outerlimits SV43, powered by twin Whipple-charged Teague Custom Marine 1390 hp engines with Mercury Racing Dry Sump Eight drives. In initial tests, the boat ran 152 mph, but the engines were hitting the rev limiters. Dustin expects the boat to run 160 mph on pump gas.

When Dustin and Shonda were growing up, the family always had boats. Patriarch Art was a drag racer, on land and on the water. In land-based competition, Art owned the Revelloution Funny Car that Ed “The Ace” McCulloch drove. The duo won the 1970 NHRA US Nationals and the 1971 Winternationals.

Art retired from racing to start his family but then started tuning for his father-in-law Ed Wills and his Top Fuel Funny Cars and drag boats, under the Mr. Ed and Whipple & Mr. Ed brands. The Mr. Ed Top Fuel drag boat was the first to top 200 mph.

In 1987, Art Whipple got back into performance. He discovered an Australian company called Sprintex that made twin-screw superchargers and adapted it to his own Chevy Silverado pickup. Soon, Whipple Industries became the sole U.S. distributor for Sprintex Superchargers. In 1991, Art Whipple discovered a Swedish company called Opcon Autorotor, a sister company to Svenska Rotor Maskiner (SRM). SRM offered a larger variety of twin-screw blowers.

When Autorotor and SRM split, Whipple stayed with SRM and their new company Lysholm Technologies. In 2004, the Lysholm/Eaton compressor was used on the Ford GT super car and Mercury Racing High Performance engines.

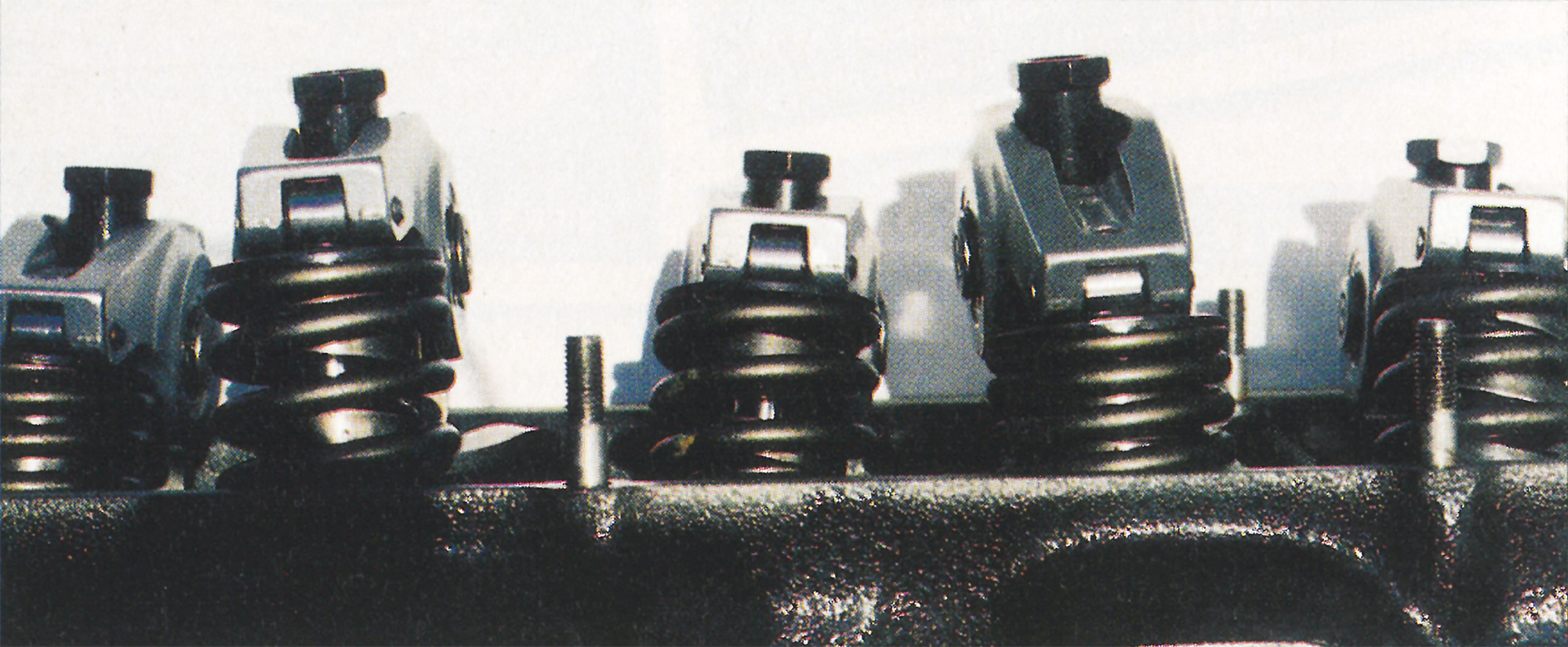

After problems with a merger between Lysholm and the Opcon Group resulted in little output of twin-screw compressors, Art Whipple decided to develop his own superchargers. The Whipple product offered reduced noise levels and a high-flow rotor coating for increased efficiency and durability. The new design also provided for increased bearing lubrication for lower operating temperatures, which eliminates the need for an intercooler. Reliability is enhanced thanks to a double angular front bearing and an oil sight glass that lets you easily check the lubricant level.

Compared to other types of superchargers, the Whipple is the only blower with a positive displacement design that produces efficiency from the bottom of the rpm range to wide open throttle. Centrifugal-style blowers and turbochargers can have lag time during shift points and on-off throttle sequences. Old-school roots-type blowers have shown less efficiency at higher boost levels.

“We offer a blower that’s half the physical size of their supercharges and we’re 40 to 50 percent more expensive than a roots,” said Dustin. “But we can fit 1300 hp in such a tight package that it’s really hard to compete with us in any way.”

One of the most attractive attributes of a Whipple supercharger is they rarely require any engine hatch modifications to fit in a given boat.

The 1,000 available Whipple kits for marine use range from a 100-cubic inch compressor to a 510-ci unit and the superchargers can be used on MerCruiser and Mercury Racing models, ranging from the 350 MAG MPI to increasing power on models such as the HP1075 SCi. The most popular kit is for the Mercury Racing HP525 EFI that Dustin Whipple said makes 800 hp at 7 psi.

A 496 kit with the computer raises horsepower output to 620 hp and costs $7,995. Upgrade a MerCruiser HP 850 SCi with a new Whipple supercharger, computer and all required components and pay $3,295 to take output to 1150 hp.

However, it was collaboration with Bob Teague, owner of Teague Custom Marine in Valencia, CA. that may have been the most important project that Whipple has worked on. Dustin set up a Whipple supercharger on a MerCruiser 502 MAG MPI in a Carrera 25’ catamaran. Then he, Teague and Matt Trulio, who was then the editor at Powerboat magazine, took a ride and Teague and Trulio were blown away.

From there, it was word of mouth and Dustin’s hustle that got his products into boats on the West Coast. In addition to Teague Custom Marine, Dustin Whipple approached many other engine builders, explaining to them, “I can offer you the computer, injector, and manifolds that will work on all your big block engine combinations,” explained Dustin. “We gave them the air/fuel solution.”

The relationship with Teague Custom Marine continued when Bob Teague decided to make his entire model line compliant with California Air Resources Board (CARB) emissions compliance. “It took both of us to get the projects up and going,” explained Whipple. “They already had a good platform, so we didn’t have to do too much R and D on the engines themselves,” he said.

Whipple eventually worked its way into the East Coast market with companies such as Chief Engines, Potter Performance and Precision Marine. Today, virtually every performance engine builder in the marine industry turns to Whipple Superchargers for supercharger applications. For all of the 1,000 supercharger kits available to the marine industry, Dustin does nearly all the computer work and is constantly testing on a dynamometer at the Whipple headquarters in Fresno and real world testing in the boats all over the world.

“We spent millions in the last 15 years building engines, dynos, and testing,” says Dustin. “We don’t have a huge staff as far as sales people and we put all the money back into the product. The reason we continue in marine is we did a major initial investment and now it’s picking back up.”

The best endorsement for Whipple superchargers is the plethora of customers who use their boats every weekend for hours at a time at full throttle.

“We have a majority of customers who have our products on their boat and they’ve proven that they can make it from point A to Point B and have plenty of power on demand, yet when you want to idle around, its like it was stock package.” said Dustin. PRA