Weldon electric marine fuel pumps have been one of the top choices among the go-fast crowd and high-performance engine manufacturers for decades, providing proven dependability under extreme situations season after season.

Perhaps that’s what prompted Mercury Racing to utilize these pumps for supplying fuel to their supercharged electronic fuel-injected engines. Weldon electric marine fuel pumps are water-resistant, but not necessarily water-proof, which makes a huge difference when it comes to protecting the pump.

After a day on the water, when washing down the engine with a hose or pressure washer, more often than not, the stream is applied directly on the fuel pump and water can be forced past the seals into its motor. Since there is no way for this water to escape, the grease in the bearings is eventually washed away by the water, causing the pump motor to fail.

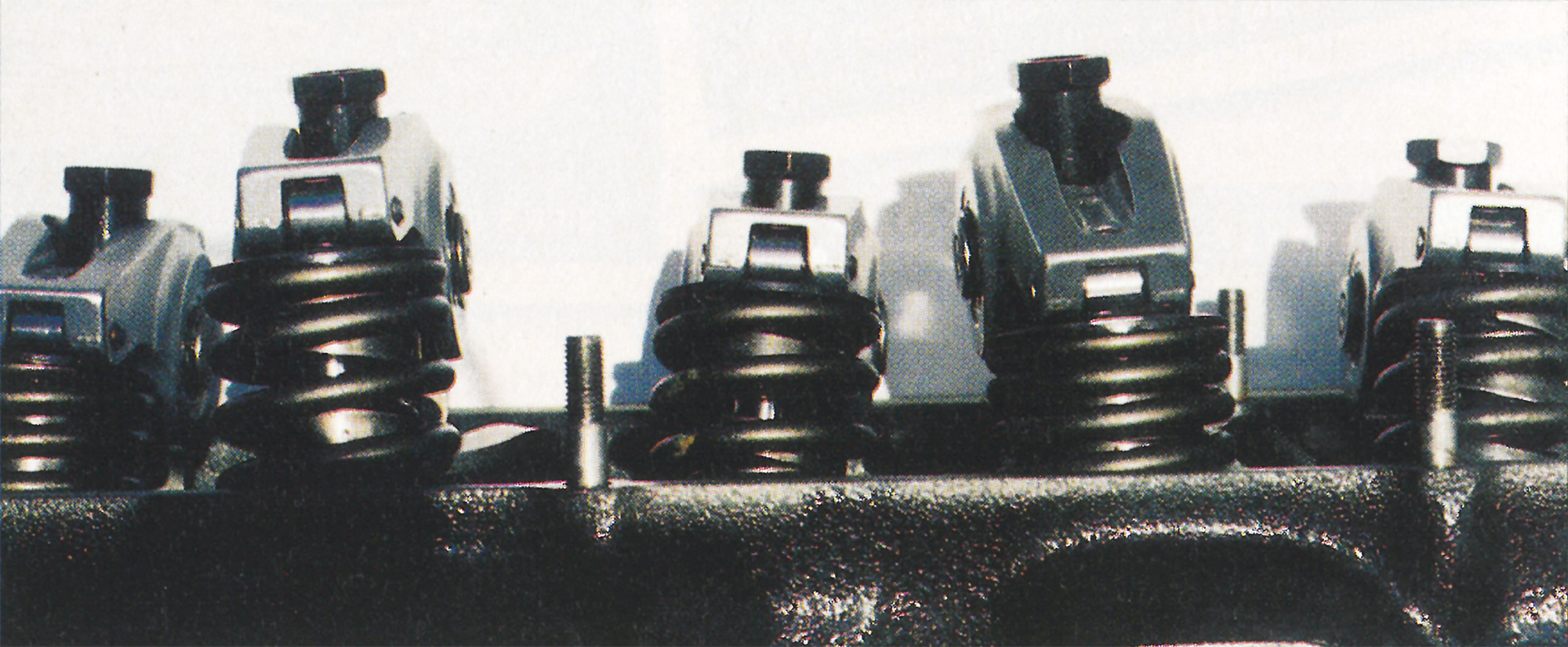

It isn’t usually the pump itself that fails, but the motor that drives it. There is very little clearance between the armature of the motor, (the part in the photo with copper wire wrapped around it) and the fields of the motor. When the ball bearing fails, the armature contacts fields in the motor and grounds out, then the motor can no longer run to drive the pump.

To order a back issue call (800) 461-9128 or sign in to read entire article

Fortunately the motor can be replaced. Better yet, the problem can be prevented by simply covering the pump with plastic or some other water-proof material to protect it when washing the engines. Then remove the covering, and apply a little WD40 (or similar rust and corrosion inhibiting solution) on the pump with a cloth or paper towel.

According to Weldon racing pumps, in some instances it’s actually the placement of the fuel pump in most boats that promote this premature bearing failure. For instance, it’s recommended to lay the fuel pump on its side (horizontally) in an effort to prevent the water and moisture from gathering at the base of the fuel pump that results in water-logging the bearing, which in turn, rusts and causes the bearing to fail (you’ll notice the bearing “going away” by an odd high-pitched squeal emitting from the fuel pump). While this is plenty of warning, most boaters fail to hear it due to all the other sounds coming from the engine area.

Additionally, as the bearing begins to “dry out”, the amp draw of the motor begins to increase resulting in popped breakers or blown fuses (and as we stated before there is usually nothing wrong with the pumping element –– it’s a motor issue that can be easily repaired).

On another note, if the pump is submerged, the first thing to do is to remove the motor, carefully remove the bottom aluminum spacer (in between steel motor housing and pump end) and liberally douse it with WD40 or good electrical contact cleaner as this will stop rust from forming and dispel all moisture. Also, liberally douse the pump cavity (that is exposed once the motor is removed). If at all possible, remove the fuel lines and fill the pump cavity (through the pump’s inlet port) with light weight oil. Be sure to place a plug or cap into both the outlet and inlet port to prevent oil from just running out. Then just send the “damaged” fuel pump to Weldon Racing and they’ll make sure it’s ok to use as these pumps are completely rebuildable.