At the invitation of Dart Manufacturing’s Jack McInnis, Poker Runs America’s tech department was given the opportunity to test a new set of its marine aluminum heads. These heads were completely stock and out of the box. This was the perfect opportunity, as our technical expert, Price Turner, happened to have a set of engines available that were due for upper block maintenance. What better time to install the new heads?

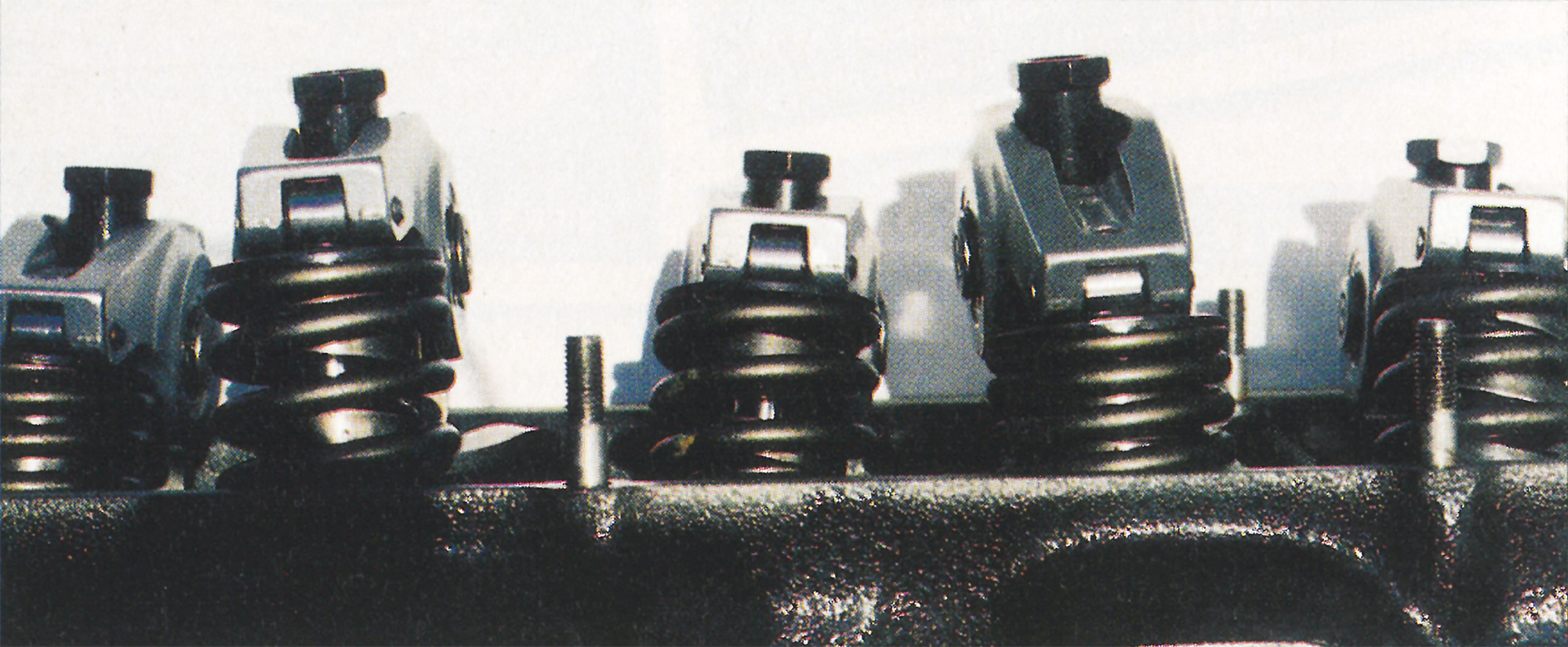

Price also received a set of Jesel rockers and components for evaluation. John Pompi, of Marine Performance in Port Orange, Florida, removed the big 540 blocks from the hull and delivered them to us. Since Dart Manufacturing is located in Michigan only minutes away from Sterling Performance, we had the motors shipped there for disassembly and rebuilding.

The motors had a full season of poker runs on them, and after a complete leak down and compression tests, everything looked okay, meaning the pistons and rings would not require replacement. When they ran the engines on the dyno prior to disassembly, they delivered 983 hp.

Now it was time to tear them down and remove the carburetors, superchargers, headers, intake manifolds, push rods, lifters and the rocker assemblies. From there, Sterling removed the heads and dismantled the valves and springs. We were astonished with the minimal wear evidenced on the lifters and valve assembly. The Crane cam had very little wear, even after a full season of poker run events, running the engines on Mobile One 15W50 synthetic oil no doubt contributed to their minimal wear factor.

In fact, the only area of concern was an indication of a possible head gasket leak forthcoming in the future. This discovery only reinforced the value in performing regular scheduled maintenance on high performance, supercharged engines.

At the invitation of Dart Manufacturing’s Jack McInnis, Poker Runs America’s tech department was given the opportunity to test a new set of its marine aluminum heads. These heads were completely stock and out of the box. This was the perfect opportunity, as our technical expert, Price Turner, happened to have a set of engines available that were due for upper block maintenance. What better time to install the new heads?

Price also received a set of Jesel rockers and components for evaluation. John Pompi, of Marine Performance in Port Orange, Florida, removed the big 540 blocks from the hull and delivered them to us. Since Dart Manufacturing is located in Michigan only minutes away from Sterling Performance, we had the motors shipped there for disassembly and rebuilding.

The motors had a full season of poker runs on them, and after a complete leak down and compression tests, everything looked okay, meaning the pistons and rings would not require replacement. When they ran the engines on the dyno prior to disassembly, they delivered 983 hp.

Now it was time to tear them down and remove the carburetors, superchargers, headers, intake manifolds, push rods, lifters and the rocker assemblies. From there, Sterling removed the heads and dismantled the valves and springs. We were astonished with the minimal wear evidenced on the lifters and valve assembly. The Crane cam had very little wear, even after a full season of poker run events, running the engines on Mobile One 15W50 synthetic oil no doubt contributed to their minimal wear factor. In fact, the only area of concern was an indication of a possible head gasket leak forthcoming in the future.

To order a back issue call (800) 461-9128 or click here to subscribe…TBD